This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

MotionMind AI for Industrial Safety

Enhance industrial safety using MotionMind AI’s cutting-edge computer vision. Easily added to existing surveillance systems, MotionMind AI spots and reports PPE non-compliance, unauthorized entries, and more for immediate action.

How MotionMind AI can be applied in your industry

Safety is a big challenge, no matter your field—manufacturing, oil and gas, construction, logistics, or energy. MotionMind AI keeps an eye on safety as it happens.

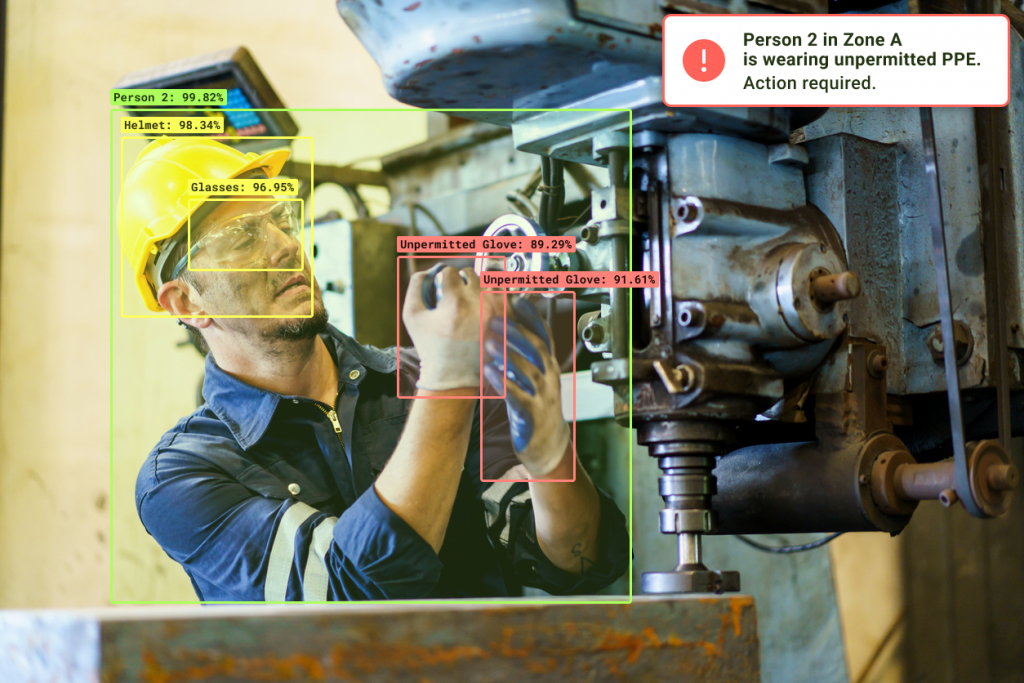

PPE compliance

Challenge: The nature of physical work increases accident risks. Without full visual monitoring, ensuring PPE use is tough, leading to potential injuries and fines.

Our approach: MotionMind AI automates the monitoring of PPE use across various scenarios—be it helmets, goggles, gloves, vests, safety boots, or any custom items. With real-time alerts for any lapses, it helps cut the risk of accidents and avoid costly penalties, all while keeping operations running smoothly.

Intrusion detection

Challenge: Power plants, with complex sites and critical infrastructure, are particularly tough to monitor continuously. However, keeping these high-risk facilities secure is crucial.

Our approach: MotionMind AI enhances your facility’s security through live visual monitoring and immediate alerts for any abnormal activity or unauthorized entry along your perimeter. It safeguards sensitive equipment, prevents accidents with severe consequences and costly downtimes, and aids in post-incident analysis.

Occupancy Counting

Challenge: The critical moment in any emergency—be it a fire, a structural collapse, or a hazardous material leak—is knowing who is on-site. This helps with rapid evacuation and saves lives.

Our approach: Using sophisticated computer vision technology, MotionMind AI ensures precise occupancy counts. This capability not only enables an immediate emergency response in crisis situations but also reinforces daily operational safety in dynamic environments like construction sites.

Machine & lifting safety

Challenge: Operating machinery and lifting in workplaces can lead to injuries without safe practices. Monitoring these tasks for safety is essential, yet challenging.

Our approach: Leveraging its cutting-edge human pose estimation capabilities, MotionMind AI watches over machine use and lifting in real time. It spots unsafe actions fast, enabling immediate corrective action to reduce the risk of injury and ensure adherence to safety protocols.

Fall/slip detection

Challenge: In the dynamic environments of manufacturing, warehousing, or construction, every second counts when it comes to responding to falls or slips. Yet, they are often hard to monitor in real time due to the vastness and complexity of these sites.

Our Approach: With advanced human pose estimation, MotionMind AI is your eyes on the ground, providing continuous surveillance to identify fall or slip incidents the moment they happen. By delivering immediate alerts to authorities, our system facilitates rapid assistance, minimizes injury risks, and upholds operational continuity.

Fatigue & break compliance detection

Challenge: Long shifts and physically demanding tasks increase fatigue risk, affecting worker safety and productivity. Unauthorized breaks or idle time can disrupt workflow and compromise site safety, making oversight critical for both safety and efficiency.

Our Approach: MotionMind AI detects signs of fatigue or unauthorized breaks and identifies idle time in inappropriate zones. By monitoring in real-time and producing automated alerts, it provides actionable insights to manage worker energy levels and compliance, optimizing shift schedules and boosting productivity.

Unauthorized object detection

Challenge: In high-stakes environments like manufacturing floors, even a small unauthorized object—such as stray cables, misplaced tools, or loose packaging materials—can become a serious safety hazard. Such items not only increase the risk of slips, trips, and equipment jams but also disrupt workflow and can lead to costly downtime.

Our Approach: MotionMind AI continuously scans the production floor for unauthorized or misplaced objects, leveraging advanced object recognition. When an item is detected, the system immediately alerts floor managers to prevent potential accidents, maintaining a clear and safe workspace.

Added benefit: Material tracking for production

Challenge: Managing diverse materials, like pipes and metal components, across complex environments—steelworks, construction sites, manufacturing plants, and oil & gas facilities—is often difficult without real-time tracking. This can lead to production delays, misallocations, and inventory inaccuracies.

Our Approach: MotionMind AI automates material identification and tracking, continuously logging specifications, quantities, and batch details. This precise tracking streamlines material allocation, allowing production leads to instantly verify availability for specific orders. By integrating with inventory systems, our system updates stock levels in real time, triggering alerts when materials fall below required thresholds.

What makes MotionMind AI a perfect fit for your industry’s safety needs?

Using computer vision and deep learning algorithms, MotionMind AI analyzes live footage from surveillance cameras, demonstrating unparalleled accuracy in object and human movement recognition. Its key features include:

Precision

Reconstructs every movement, from obscured to partial views, without errors into detailed 3D models using any camera setup. This is achieved in real time or near real time for a rapid response.

Customization

Quickly learns to identify any safety violation specific to your site. As your safety needs evolve, you can add more detection and tracking patterns using an intuitive admin panel.

Intelligent response

Provides AI-based alerts, coupled with human intervention options, to industrial safety managers and emergency response teams.

Cost effectiveness

Ready to work with any cameras, regardless of the model or make, eliminating the need for expensive hardware upgrades or the purchase of specific camera systems.

Contact us